Exploring The Uses And Benefits Of Horizontal And Vertical Autoclaves

Are you curious about the uses and benefits of horizontal and vertical autoclaves? Look no further! In this comprehensive guide, we will delve into the world of autoclaves, exploring how these essential pieces of equipment are transforming industries and ensuring a safe and sterile environment. Join us as we uncover the advantages of both horizontal and vertical autoclaves, and learn why they are an indispensable tool in various settings. Whether you are a scientist, medical professional, or researcher, this article is a must-read for anyone seeking to understand the importance of autoclaves in today's world.

- Understanding the Differences between Horizontal and Vertical Autoclaves

Autoclaves are essential equipment in scientific, medical, and industrial settings for sterilizing tools, equipment, and materials. Understanding the differences between horizontal and vertical autoclaves is crucial for choosing the right one for specific applications. In this article, we will explore the uses and benefits of both types of autoclaves to help you make an informed decision.

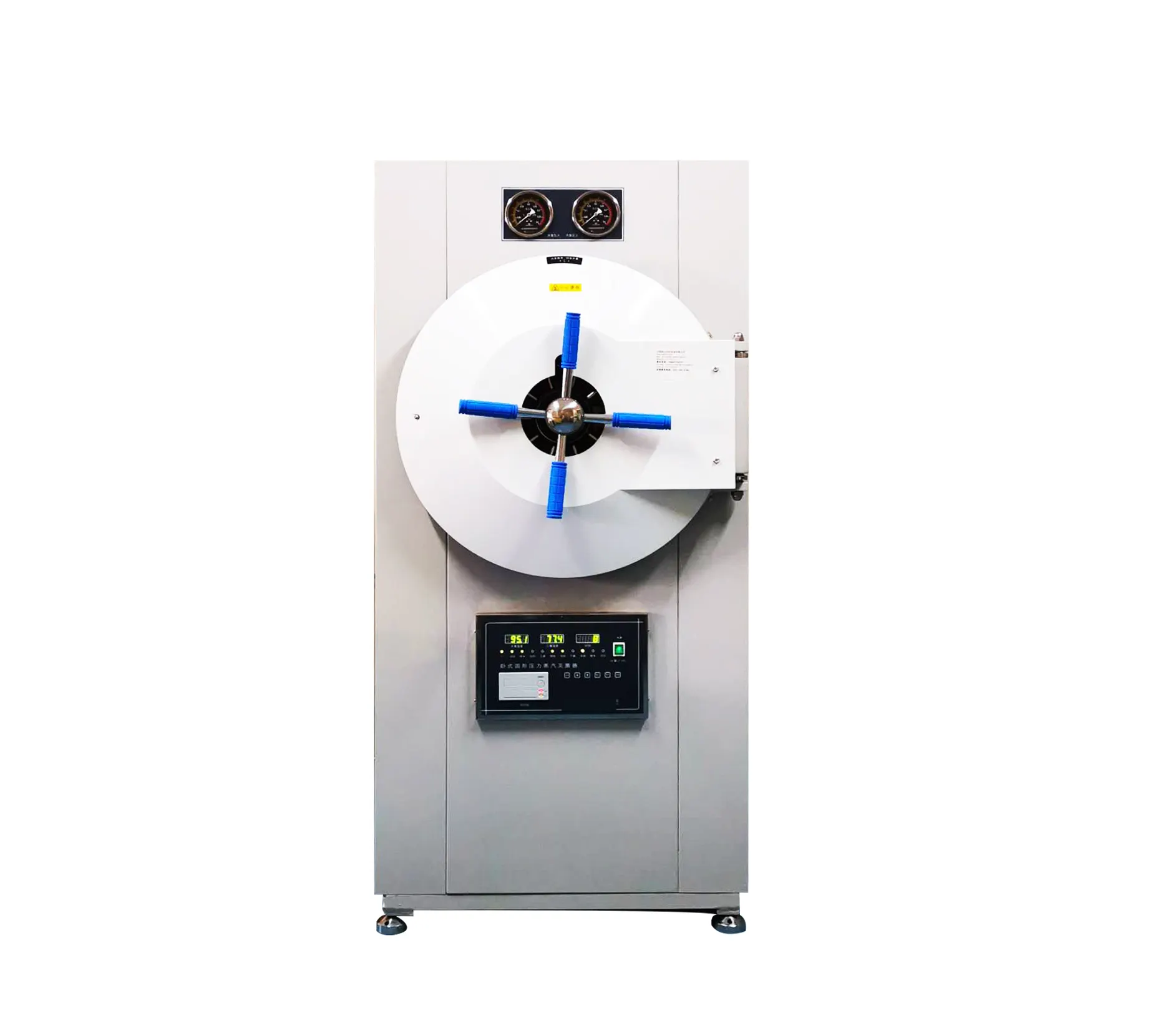

Horizontal Autoclaves:

Horizontal autoclaves are designed with rectangular chambers that facilitate the loading and unloading of materials. Their horizontal orientation allows for easy access to the chamber, making them ideal for sterilizing larger or longer items such as surgical instruments, glassware, and laboratory containers. Horizontal autoclaves typically have sliding doors or swing doors that open to the side, providing convenient access to the sterilization chamber.

One of the main advantages of horizontal autoclaves is their versatility in accommodating various types and sizes of materials. They are also space-saving, as they can be placed under workbenches or countertops. Horizontal autoclaves are commonly used in research laboratories, hospitals, and pharmaceutical facilities for sterilizing bulky items that may not fit in vertical autoclaves.

Vertical Autoclaves:

Vertical autoclaves feature a cylindrical chamber that is oriented vertically, with a top-loading door for easy access to the sterilization chamber. Vertical autoclaves are ideal for sterilizing small to medium-sized items such as glassware, petri dishes, and biohazardous waste. They are compact in size and are often used in dental clinics, veterinary clinics, and small research laboratories.

The main advantage of vertical autoclaves is their efficient use of space, as they can be placed on countertops or cabinets without taking up much room. They are also more energy-efficient compared to horizontal autoclaves, as the steam circulates more evenly in the chamber due to its vertical orientation. Vertical autoclaves are designed for quick sterilization cycles, making them efficient for busy work environments that require frequent sterilization of small loads.

Key Differences between Horizontal and Vertical Autoclaves:

The key differences between horizontal and vertical autoclaves lie in their design, chamber orientation, and loading mechanisms. Horizontal autoclaves are suitable for sterilizing large or long items, while vertical autoclaves are better suited for small to medium-sized items. Horizontal autoclaves are versatile and space-saving, while vertical autoclaves are compact and energy-efficient.

In conclusion, both horizontal and vertical autoclaves have their uses and benefits depending on the specific requirements of the application. By understanding the differences between these two types of autoclaves, you can choose the one that best suits your needs for efficient and effective sterilization practices.

- The Various Applications of Horizontal Autoclaves in Different Industries

Autoclaves are vital equipment used in various industries for sterilization purposes. Horizontal and vertical autoclaves are two commonly used types, each with its own set of applications and benefits. In this article, we will delve into the various applications of horizontal autoclaves in different industries.

Horizontal autoclaves are widely used in the pharmaceutical industry for sterilizing medical instruments, laboratory equipment, and production materials. These autoclaves are designed with horizontal chambers that allow for easy loading and unloading of bulky items such as large containers, trays, and glassware. The horizontal orientation of these autoclaves also ensures uniform distribution of heat and steam, resulting in effective sterilization of sensitive materials.

In the food and beverage industry, horizontal autoclaves play a crucial role in preserving and extending the shelf life of packaged products. These autoclaves are used for sterilizing canned foods, ready-to-eat meals, and beverages in order to eliminate harmful bacteria and ensure product safety. The horizontal design of these autoclaves enables efficient processing of large batches of products, thereby increasing productivity and reducing operational costs.

Another industry that heavily relies on horizontal autoclaves is the pharmaceutical sector, where these autoclaves are used for sterilizing medical instruments, laboratory equipment, and production materials. The horizontal orientation of these autoclaves allows for easy loading and unloading of bulky items, making them ideal for handling large containers, trays, and glassware. The uniform distribution of heat and steam in horizontal autoclaves ensures thorough sterilization of sensitive materials, thereby maintaining compliance with industry regulations.

In the research and development sector, horizontal autoclaves are utilized for sterilizing biohazardous waste, laboratory equipment, and culture media. These autoclaves are designed with advanced features such as programmable cycles, temperature control, and pressure monitoring to ensure precise sterilization of delicate materials. The horizontal chambers of these autoclaves provide ample space for accommodating irregularly shaped items and large volumes of waste, making them essential equipment for research facilities and academic institutions.

Overall, horizontal autoclaves offer a versatile and efficient solution for sterilization needs across various industries. Their horizontal orientation, uniform heat distribution, and advanced features make them an indispensable tool for ensuring product safety, compliance with industry regulations, and operational efficiency. Whether it is sterilizing medical instruments in the pharmaceutical industry or preserving canned foods in the food and beverage sector, horizontal autoclaves continue to play a pivotal role in maintaining high standards of hygiene and quality assurance.

- Advantages of Vertical Autoclaves in Laboratory Settings

Autoclaves are essential tools in laboratory settings for sterilizing equipment, materials, and even biological waste. Horizontal and vertical autoclaves are two common types used in research facilities, hospitals, and pharmaceutical companies. While both types have their own advantages, vertical autoclaves offer unique benefits that make them a popular choice in many laboratory settings.

One of the key advantages of vertical autoclaves is their space-saving design. Unlike horizontal autoclaves that require a larger footprint, vertical autoclaves are tall and narrow, making them ideal for laboratories with limited space. This compact design allows researchers to maximize their workspace and optimize the layout of their laboratory.

Vertical autoclaves also offer greater loading capacity compared to horizontal autoclaves. The vertical orientation of the chamber allows for more vertical space, enabling researchers to sterilize more equipment or materials in a single cycle. This increased loading capacity is particularly beneficial for laboratories with high throughput or large batches of items to sterilize.

Another advantage of vertical autoclaves is their ease of use. With a vertically oriented chamber, loading and unloading items is a simpler and more ergonomic process. Researchers can easily access items at eye level, reducing the risk of injury or strain from bending or reaching. This user-friendly design also allows for quick and efficient operation, saving valuable time in busy laboratory environments.

In addition, vertical autoclaves offer superior sterilization performance. The vertical orientation of the chamber allows for more efficient air removal, ensuring thorough sterilization of all items inside. This helps to eliminate the risk of contamination and ensures that items are properly sterilized before use. Vertical autoclaves are also equipped with advanced safety features, such as automatic pressure and temperature controls, to prevent accidents and ensure the safety of laboratory personnel.

Overall, vertical autoclaves are a versatile and practical choice for laboratory settings. Their space-saving design, increased loading capacity, ease of use, and superior sterilization performance make them an ideal solution for researchers and professionals in various fields. Whether sterilizing equipment, materials, or biological waste, vertical autoclaves provide efficiency, reliability, and convenience in laboratory sterilization processes.

In conclusion, when it comes to choosing between horizontal and vertical autoclaves, the advantages of vertical autoclaves make them a preferred option for many laboratory settings. With their unique benefits and advanced features, vertical autoclaves offer an effective and efficient solution for sterilizing items in research facilities, hospitals, and pharmaceutical companies.

- Exploring the Unique Features of Horizontal Autoclaves for Specific Sterilization Needs

When it comes to ensuring thorough sterilization in laboratory and medical settings, autoclaves are a vital piece of equipment. These devices use high pressure and steam to effectively kill any bacteria, viruses, and other microorganisms on instruments and equipment. There are two main types of autoclaves: horizontal and vertical. Each type has its own unique features and benefits, making them suitable for specific sterilization needs.

Horizontal autoclaves, as the name suggests, have a horizontal chamber where the items to be sterilized are placed. This design allows for easy loading and unloading of bulky items such as glassware, liquids, and other large equipment. The horizontal orientation also allows for more even distribution of steam and heat throughout the chamber, ensuring thorough sterilization of all surfaces. Additionally, horizontal autoclaves are often equipped with advanced programming options, making it easy to adjust cycle times and temperatures for different types of materials.

One of the key advantages of horizontal autoclaves is their versatility in terms of sterilization needs. These autoclaves are ideal for sterilizing liquids, as the horizontal orientation allows for minimal liquid loss during the sterilization process. This is crucial for laboratories working with sensitive or expensive liquids that need to be preserved. Horizontal autoclaves are also well-suited for sterilizing large pieces of equipment or multiple items at once, making them efficient for busy laboratories or medical facilities.

In contrast, vertical autoclaves have a chamber that is oriented vertically, with the items to be sterilized stacked on top of each other. While vertical autoclaves may not have the same loading capacity as horizontal autoclaves, they are still highly effective for sterilizing small, solid items such as glassware, surgical instruments, and other laboratory tools. Vertical autoclaves are also known for their compact size, making them a good choice for facilities with limited space.

One of the main benefits of vertical autoclaves is their quick heating and cooling times. The vertical orientation allows for rapid steam circulation, ensuring a fast and efficient sterilization process. This is particularly important for laboratories or medical facilities with high turnover rates of equipment that needs to be sterilized quickly and frequently. Vertical autoclaves are also popular for their ease of use and minimal maintenance requirements, making them a practical choice for busy settings.

In conclusion, both horizontal and vertical autoclaves have their own unique features and benefits that make them suitable for different sterilization needs. Horizontal autoclaves excel in sterilizing large or bulky items, while vertical autoclaves are ideal for small, solid objects. Understanding the specific sterilization requirements of your laboratory or medical facility will help you determine which type of autoclave is best suited for your needs. Ultimately, investing in a high-quality autoclave is essential for maintaining a clean and safe working environment.

- Maximizing Efficiency and Safety with the Use of Horizontal and Vertical Autoclaves

Autoclaves are essential pieces of equipment in various industries such as healthcare, research, and manufacturing. They are used for sterilizing equipment, materials, and other items to prevent the spread of infections and maintain safety standards. In this article, we will explore the various uses and benefits of both horizontal and vertical autoclaves, focusing on how they can maximize efficiency and safety in different settings.

Horizontal autoclaves are designed for sterilizing larger items such as trays, containers, or bulky equipment. They are ideal for facilities that have limited vertical space but need to sterilize a high volume of items on a regular basis. The horizontal orientation allows for easy loading and unloading of items, making the sterilization process more efficient. Additionally, horizontal autoclaves are often equipped with advanced features such as programmable cycles, automatic controls, and safety interlocks to ensure proper sterilization and prevent accidents.

Vertical autoclaves, on the other hand, are designed for sterilizing smaller items such as test tubes, petri dishes, or laboratory instruments. They are commonly used in research labs, medical facilities, and pharmaceutical companies where space is not an issue. Vertical autoclaves have a smaller footprint compared to horizontal autoclaves, making them ideal for facilities with limited space. They also have a faster cycle time, allowing for quicker turnaround of sterilized items.

Both horizontal and vertical autoclaves offer numerous benefits when it comes to sterilization. Firstly, they provide a reliable and effective method of sterilizing various items, eliminating bacteria, viruses, and other harmful microorganisms. This helps prevent the spread of infections and ensures the safety of personnel and patients in healthcare settings. Additionally, autoclaves offer a cost-effective solution for sterilization, reducing the need for disposable items and saving money in the long run.

Furthermore, autoclaves are environmentally friendly as they use steam under pressure to sterilize items, eliminating the need for harmful chemicals. They also have a low energy consumption, making them an energy-efficient option for sterilization. Moreover, autoclaves are easy to operate and maintain, requiring minimal training for personnel to use them effectively.

In conclusion, horizontal and vertical autoclaves are essential equipment for maximizing efficiency and safety in various industries. Whether it is sterilizing large equipment or small laboratory items, autoclaves offer a reliable and cost-effective solution for maintaining hygiene and preventing infections. With their advanced features and ease of use, autoclaves play a crucial role in ensuring the safety of personnel and patients in healthcare facilities, research labs, and manufacturing plants.

Conclusion

In conclusion, after exploring the uses and benefits of horizontal and vertical autoclaves in various industries, it is clear that these sterilization devices play a crucial role in maintaining a clean and safe working environment. Whether it's in a medical setting, laboratory, or pharmaceutical facility, autoclaves are essential for sterilizing equipment and preventing the spread of infections. With 10 years of experience in the industry, our company understands the importance of providing high-quality autoclaves that meet the specific needs of our customers. By investing in reliable autoclave equipment, businesses can ensure the safety of their employees and the quality of their products. As technology advances, we look forward to continuing to innovate and improve our autoclave offerings to better serve our customers and the industries we support.

Contact: Ms Karen Yon

Tel: 86-18217232862

E-mail: kareny@ro-chainmed.com

WhatsApp: 86-18217232862

Add: Room 207, Building 1, Kangqiao Road 787, Pudong New District, Shanghai, China 201315