Exploring The Efficiency Of Horizontal Autoclave Machines In Sterilization Processes

Are you curious about the effectiveness of horizontal autoclave machines in sterilization processes? Look no further! This article delves into the exploration of the efficiency of these machines and their vital role in ensuring proper sterilization procedures. Join us as we uncover the ins and outs of horizontal autoclave machines and discover why they are a crucial component in maintaining a safe and hygienic environment.

The Importance of Sterilization in Healthcare Settings

Sterilization is a critical component of any healthcare setting as it plays a key role in preventing the spread of infections and ensuring the safety of patients and healthcare workers. The importance of sterilization cannot be overstated, as even a small oversight in the sterilization process can have serious consequences. It is for this reason that healthcare facilities invest in top-of-the-line sterilization equipment, such as horizontal autoclave machines, to ensure the efficiency and effectiveness of their sterilization processes.

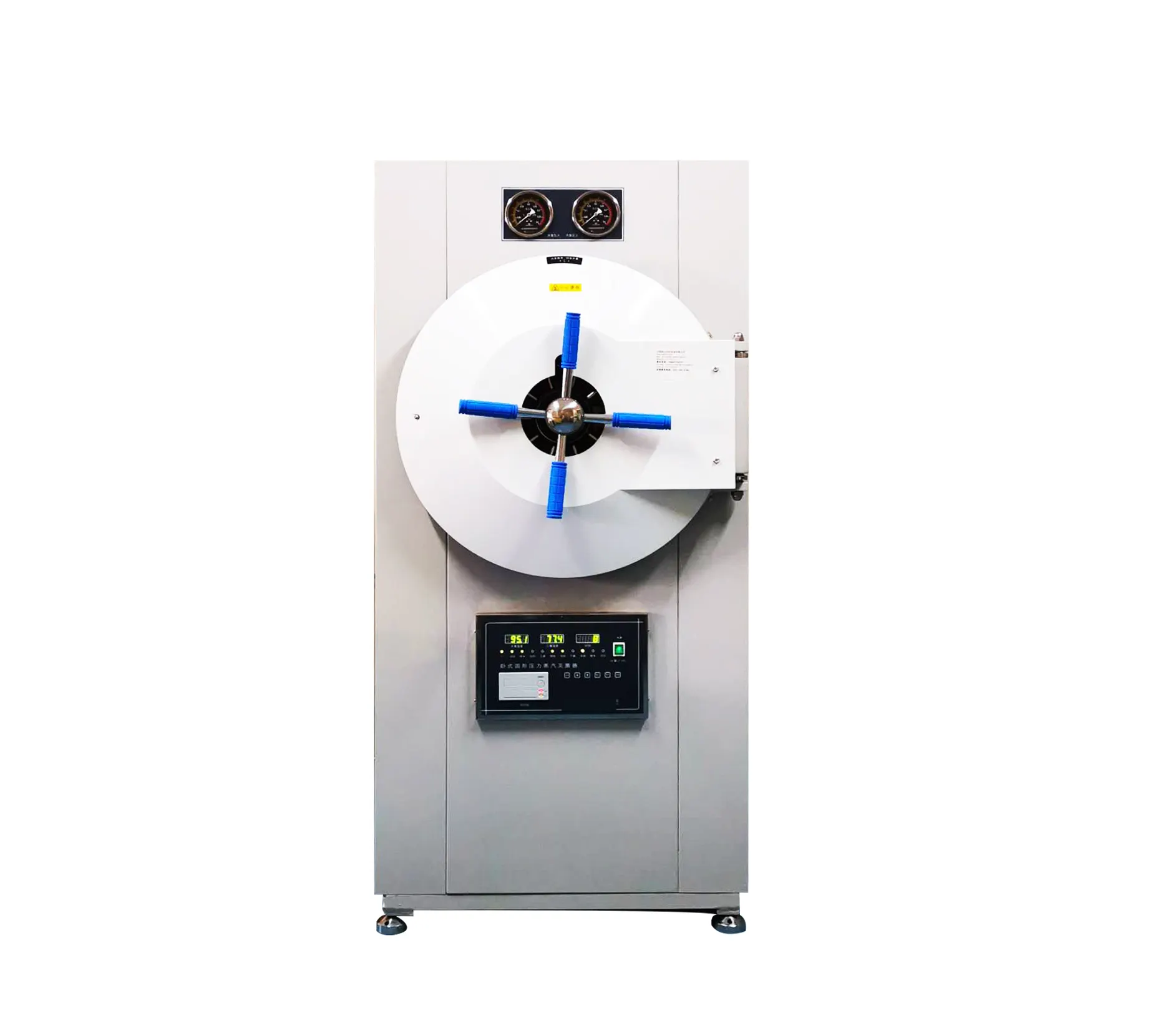

Horizontal autoclave machines are widely used in healthcare settings for sterilizing medical equipment, surgical instruments, and other items that come into contact with patients. These machines use high-pressure steam to kill pathogens and bacteria, ensuring that items are thoroughly sterilized before being used on patients. The efficiency of horizontal autoclave machines in the sterilization process is crucial, as it directly impacts the safety and well-being of patients.

One of the key advantages of horizontal autoclave machines is their ability to sterilize large quantities of items in a single cycle. This makes them ideal for busy healthcare settings where time is of the essence. Horizontal autoclave machines are also designed to be user-friendly, with intuitive controls and automated features that streamline the sterilization process. This allows healthcare workers to focus on providing quality care to patients, rather than spending excessive time on sterilization tasks.

In addition to their efficiency, horizontal autoclave machines are also known for their reliability. These machines are built to withstand rigorous use and are designed to deliver consistent results each time they are used. This reliability is essential in healthcare settings, where the sterilization of medical equipment is a non-negotiable aspect of patient care.

Furthermore, horizontal autoclave machines are equipped with safety features that help prevent accidents and ensure the well-being of healthcare workers. These features include automatic shutoff mechanisms, pressure sensors, and temperature controls that help maintain a safe working environment. By prioritizing safety, horizontal autoclave machines help healthcare facilities maintain high standards of care and protect the well-being of their staff.

In conclusion, the efficiency of horizontal autoclave machines in the sterilization process is essential for maintaining the safety and well-being of patients in healthcare settings. These machines offer a range of benefits, including their ability to sterilize large quantities of items, their reliability, and their safety features. By investing in top-of-the-line sterilization equipment, healthcare facilities can ensure that their sterilization processes are as effective and efficient as possible, ultimately leading to better patient outcomes.

Understanding the Functioning of Horizontal Autoclave Machines

Sterilization processes are a critical aspect of numerous industries, from healthcare to food production and pharmaceuticals. One of the key tools utilized in the sterilization process is the horizontal autoclave machine. These machines are essential for ensuring that instruments, equipment, and materials are thoroughly sterilized and safe for use.

Horizontal autoclave machines operate on the principle of using high-pressure steam to kill off any microorganisms, including bacteria, viruses, and fungi, that may be present on the objects being sterilized. The efficiency of these machines is crucial in ensuring that the sterilization process is successful, as any missed contaminants could pose a significant risk to the health and safety of individuals.

One of the key aspects that must be understood when it comes to the functioning of horizontal autoclave machines is the importance of proper loading and placement of the materials to be sterilized. These machines are designed in a way that allows for even distribution of steam throughout the chamber, ensuring that all surfaces of the objects are exposed to the sterilizing agent. Improper loading can result in areas of the objects not being adequately sterilized, compromising the overall efficacy of the process.

In addition to proper loading, it is essential to understand the temperature and pressure settings of the horizontal autoclave machine. These settings are crucial in ensuring that the steam reaches the desired temperature and pressure levels necessary for effective sterilization. Monitoring and maintaining these settings throughout the sterilization process is key to achieving successful results.

Furthermore, the duration of the sterilization cycle is another key factor to consider when operating a horizontal autoclave machine. The cycle time will vary depending on the materials being sterilized, with some processes requiring longer exposure to steam to ensure thorough sterilization. Understanding the optimal cycle time for different types of materials is essential in achieving the desired level of sterilization.

Another important aspect to consider when using horizontal autoclave machines is the maintenance and calibration of the equipment. Regular maintenance and calibration are essential in ensuring that the machine functions properly and delivers consistent results. Any deviation from the recommended operating parameters could impact the efficacy of the sterilization process.

In conclusion, the efficiency of horizontal autoclave machines in sterilization processes is crucial in maintaining the health and safety standards in various industries. Understanding the functioning of these machines, from proper loading and placement of materials to monitoring temperature and pressure settings, is essential in achieving successful sterilization results. By adhering to best practices and ensuring proper maintenance, horizontal autoclave machines can effectively contribute to the overall sterilization process.

Advantages of Using Horizontal Autoclave Machines for Sterilization

Sterilization is a crucial process in various industries, including healthcare, pharmaceuticals, and laboratories, to ensure the safety and quality of products and equipment. One of the most efficient methods of sterilization is through the use of autoclave machines. In particular, horizontal autoclave machines have been gaining popularity due to their numerous advantages in the sterilization process.

One of the key advantages of using horizontal autoclave machines is their efficient design. These machines are specifically constructed to accommodate large volumes of materials and equipment, making them ideal for sterilizing multiple items at once. This is particularly beneficial in facilities where large quantities of equipment need to be sterilized on a regular basis, such as hospitals and research laboratories.

Furthermore, horizontal autoclave machines offer a high level of versatility. These machines are equipped with programmable controls that allow users to adjust settings such as temperature, pressure, and sterilization time according to the specific requirements of the materials being sterilized. This flexibility ensures that different types of items can be sterilized effectively, without compromising their integrity or quality.

In addition to their efficiency and versatility, horizontal autoclave machines are also known for their reliability. These machines are built to withstand high temperatures and pressures, ensuring thorough sterilization of materials and equipment. They are also equipped with safety features, such as automatic shut-off systems, to prevent accidents and ensure the well-being of users.

Another advantage of using horizontal autoclave machines is their cost-effectiveness. These machines are designed to operate efficiently, reducing the time and energy required for sterilization processes. This not only increases productivity but also helps to lower operational costs in the long run. Additionally, the durability of horizontal autoclave machines means that they require minimal maintenance, further reducing overall expenses.

Furthermore, horizontal autoclave machines are environmentally friendly. These machines use steam as a sterilization agent, which is a safe and sustainable method compared to chemical sterilization processes. The use of steam also ensures that materials are sterilized thoroughly, eliminating the risk of contamination and improving overall safety standards.

Overall, the efficiency of horizontal autoclave machines in sterilization processes makes them an invaluable asset in various industries. Their efficient design, versatility, reliability, cost-effectiveness, and environmental friendliness set them apart as a superior sterilization method. In conclusion, the use of horizontal autoclave machines is essential for ensuring the safety and quality of materials and equipment in a wide range of applications.

Key Factors Influencing the Efficiency of Horizontal Autoclave Machines

Horizontal autoclave machines play a crucial role in sterilization processes, ensuring that medical equipment, laboratory instruments, and other materials are free from harmful pathogens. In order to maximize the efficiency of these machines, it is important to understand the key factors that influence their performance.

One of the key factors influencing the efficiency of horizontal autoclave machines is the quality of the steam used in the sterilization process. Clean, dry steam is essential for effective sterilization, as any impurities or moisture in the steam can prevent the equipment from reaching the necessary temperature and pressure levels. Regular maintenance and testing of the steam generator, as well as the use of high-quality steam, are essential to ensure optimal performance.

Another important factor to consider is the size and design of the autoclave chamber. The size of the chamber will determine the capacity of the machine and the types of materials that can be sterilized. A larger chamber can accommodate more equipment, resulting in greater productivity and efficiency. Additionally, the design of the chamber, including features such as internal racks and shelves, can impact the circulation of steam and the distribution of heat within the chamber, influencing the effectiveness of the sterilization process.

The operating temperature and pressure of the horizontal autoclave machine are also critical factors in determining its efficiency. The temperature and pressure must be carefully controlled and monitored to ensure that they reach the necessary levels for successful sterilization. It is important to follow the manufacturer's guidelines for temperature and pressure settings and to regularly calibrate the machine to ensure accurate readings.

Proper loading and placement of materials within the autoclave chamber is another factor that can impact the efficiency of the sterilization process. Overloading the chamber or improperly positioning items can prevent the steam from reaching all areas of the equipment, leading to incomplete sterilization. It is essential to carefully arrange items within the chamber to ensure that they are exposed to the steam and heat evenly.

In addition to these factors, regular maintenance and cleaning of the horizontal autoclave machine are essential to ensure its efficient operation. Routine inspection of the machine, including checking for leaks, damaged gaskets, and other issues, can help prevent equipment malfunctions and ensure that the sterilization process is effective. Cleaning the chamber and components of the machine regularly will also help prevent the buildup of biofilm and other contaminants that can interfere with the sterilization process.

In conclusion, the efficiency of horizontal autoclave machines in sterilization processes is influenced by a variety of factors, including the quality of the steam, the size and design of the chamber, the operating temperature and pressure, the loading of materials, and maintenance practices. By understanding and addressing these key factors, healthcare facilities and laboratories can ensure that their autoclave machines operate effectively and consistently deliver safe, sterile equipment.

Recommendations for Maximizing Efficiency in Sterilization Processes with Horizontal Autoclave Machines

In the medical field, ensuring proper sterilization of equipment and instruments is crucial to prevent the spread of infection and disease. Horizontal autoclave machines are commonly used in healthcare facilities to sterilize medical devices, supplies, and instruments. These machines utilize steam under pressure to eliminate microorganisms, making them an essential part of the sterilization process.

Efficiency is key when it comes to sterilization processes, as it not only saves time but also ensures that items are properly sterilized and safe for use. In this article, we will explore the efficiency of horizontal autoclave machines in sterilization processes and provide recommendations for maximizing their effectiveness.

One of the key factors that contribute to the efficiency of horizontal autoclave machines is proper loading and arrangement of items to be sterilized. It is important to ensure that items are placed in a way that allows steam to circulate freely and reach all surfaces. Overloading the machine can lead to uneven sterilization and reduce the effectiveness of the process. By following proper loading guidelines, healthcare facilities can maximize the efficiency of their horizontal autoclave machines.

Another important aspect to consider when aiming to maximize efficiency in sterilization processes with horizontal autoclave machines is the use of appropriate sterilization cycles. Different items may require different sterilization settings based on factors such as size, material, and the level of contamination. It is essential to follow manufacturer guidelines and recommendations when selecting the appropriate cycle for each load to ensure that items are properly sterilized.

Regular maintenance and servicing of horizontal autoclave machines are also crucial in maximizing efficiency. Routine maintenance helps prevent breakdowns and ensures that the machine is operating at its full capacity. Healthcare facilities should establish a regular maintenance schedule for their autoclave machines and address any issues promptly to avoid disruptions in the sterilization process.

Proper training of staff members who operate horizontal autoclave machines is another important factor in maximizing efficiency. Ensuring that staff are knowledgeable about the operation of the machine, loading procedures, and sterilization cycles can help prevent errors and ensure that items are properly sterilized. Ongoing training and education are essential to keeping staff members informed about best practices and advancements in sterilization techniques.

In conclusion, horizontal autoclave machines play a vital role in sterilization processes in healthcare facilities. By following the recommendations mentioned above, healthcare facilities can maximize the efficiency of their horizontal autoclave machines and ensure that items are properly sterilized. Proper loading, selection of sterilization cycles, maintenance, and staff training are all key factors in achieving optimal sterilization results with horizontal autoclave machines.

Conclusion

After delving into the efficiency of horizontal autoclave machines in sterilization processes, it is evident that these machines offer a reliable and effective way to ensure the safety and cleanliness of medical equipment and supplies. With our 10 years of experience in the industry, we have witnessed firsthand the impact that these machines can have on streamlining sterilization processes and improving overall efficiency. As technology continues to evolve, we are committed to staying at the forefront of innovation and providing our customers with the best possible solutions for their sterilization needs. The use of horizontal autoclave machines is a game-changer in the field of sterilization, and we look forward to continuing to explore their potential in the years to come.

Contact: Ms Karen Yon

Tel: 86-18217232862

E-mail: kareny@ro-chainmed.com

WhatsApp: 86-18217232862

Add: Room 207, Building 1, Kangqiao Road 787, Pudong New District, Shanghai, China 201315